Brushless vs Brushed Tools

Brushless and brushed tools are two types of electric motors commonly used in power tools. While both types of motors serve the same purpose, they operate in different ways and have some unique characteristics that make them suitable for different applications.

It has become that age-old question, should I go brushless or brushed with my next cordless drill purchase? We have gathered all the ‘need to know’ facts that should make the decision process a whole lot smoother and easier to make. But first, let us talk all about brushed and brushless motors:

What is a brushed motor?

- Brushed motors, also known as DC motors, have been around for a long time and are still widely used in a variety of power tools.

- A brushed motor is made up of four basic parts: carbon brushes, a ring of magnets, an armature, and a commutator.

- The magnets and brushes are stationary, while the armature and commutator rotate together on the motor shaft within the magnets.

- They consist of a stationary set of magnets, called the stator, and a rotating set of magnets, called the rotor, which are attached to the tool’s output shaft. The rotor is surrounded by a set of carbon brushes, which contact the stator and transmit electrical current to the rotor, causing it to spin.

- When the motor is energized, a charge travels from the battery, through the brushes, and into the commutator. (The brushes are spring-loaded to maintain physical contact with the commutator.)

- The commutator then passes the charge on to the armature, which is made up of copper windings (they look like bundles of copper wire).

- The windings are magnetized by the charge and push against the stationary ring of magnets that surround it, forcing the armature assembly to spin. The spin does not stop until the charge from the battery stops.

Shop online and browse our wide selection of brushed tools below:

What is a brushless motor?

- A brushless motor loses the brushes and the commutator, and the locations of the magnets and windings are reversed.

- The magnets are on the conventional motor shaft and the copper windings of the armature are fixed and surround the shaft. Instead of brushes and a commutator, a small circuit board coordinates the energy delivery to the windings.

- Because the electronics communicate directly with the stationary windings, the tool adjusts according to the task—which is why the companies' market these as "smarter" tools.

- For example, if you're using a brushless drill to drive screws into Styrofoam, it more readily senses the lack of resistance (compared with a brushed motor) and begins to pull only what little charge it needs from the battery.

- If the tool then starts putting 3-inch screws into mahogany, it will adjust accordingly and draw more current. By contrast, a brushed motor will always run as fast as it can while in use.

- In addition, brushless motors can be more powerful overall. Because the copper windings are on the outside of the motor configuration, there is room to make them larger.

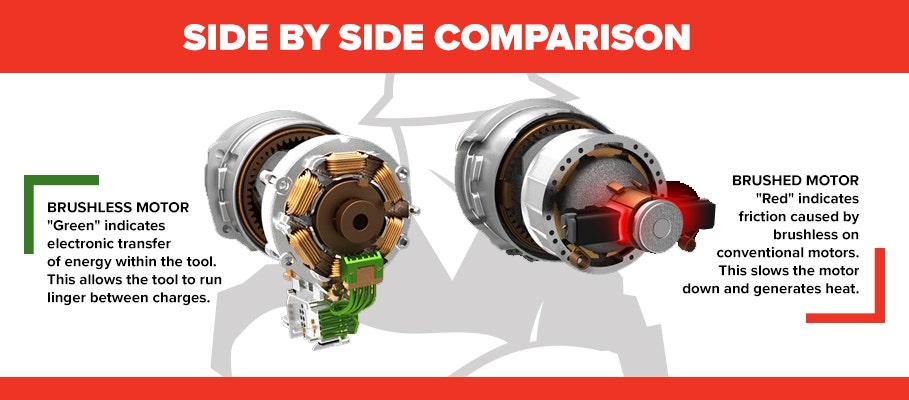

- Brushless motors also don't have the friction and voltage drop that brushes create by dragging against the spinning commutator. This physical contact results in a continuous energy loss during the operating process.

Check out our huge line of brushless tools below:

Conclusion: Brushed or Brushless?

Overall, the choice between brushed and brushless tools depends on the specific application and the needs of the user. Brushed motors are a good option for low-cost power tools that do not require important levels of performance, while brushless motors are better suited for precision tools and applications that require elevated levels of torque and speed.

In summary, brushless motors can be more powerful than your traditional brushed cordless drill. Cordless drills that utilise a brushless electronic motor are more efficient and intelligent in the way the motor regulates battery energy flow. This level of intelligence and efficiency leads to:

- Less maintenance and longer life - due to no carbon brushes

- More power - less restrictions within the motor that saps energy

- Longer run time & less battery charging - due to efficient energy use

Finding the right tool for you!

Total Tools stock a large range of brushed and brushless cordless drills, from leading manufacturers such as Makita, Milwaukee, Bosch, DeWalt, and more. You can shop the extensive cordless drill range online and in-store today!